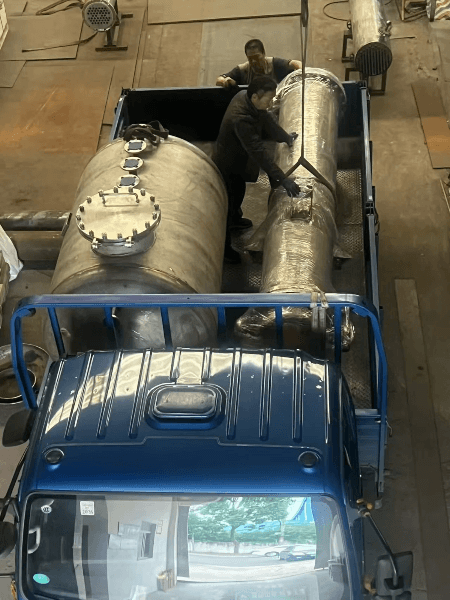

At Wuxi Repicea, we design heat exchangers that match real process conditions. Today we completed loading of a 30㎡ vertical silicon carbide (SiC) shell-and-tube heat exchanger built with a double-pass tube-side configuration and shipped it by dedicated truck to Shandong.

- Double-pass tube side

Extends the material travel distance, increases turbulence, and boosts overall heat-transfer efficiency, delivering lower outlet temperatures with the same footprint. - 304 stainless steel shell

Selected for low-temperature brine service, resisting chloride-rich freezing brines used in chilling and solvent recovery lines. - PTFE-lined stainless channel boxes

Fluoropolymer linings provide a chemically inert, non-stick surface, preventing corrosion and simplifying cleaning at turnaround. - Silicon carbide tube bundle

SiC offers high thermal conductivity, excellent chemical resistance, and thermal-shock tolerance, ensuring long life under demanding cooling duties.

Built for reliability and easy integration

The exchanger is equipped with robust flanges, precise baffle spacing, and leak-tight seals for stable operation under variable load. Connections and supports are arranged for quick tie-in to existing piping, minimizing installation time on site.

Typical applications

- Low-temperature brine cooling loops

- Solvent condensation and recovery systems

- Fine chemical and pharmaceutical process cooling

- Gas-phase condensation where corrosion resistance is critical

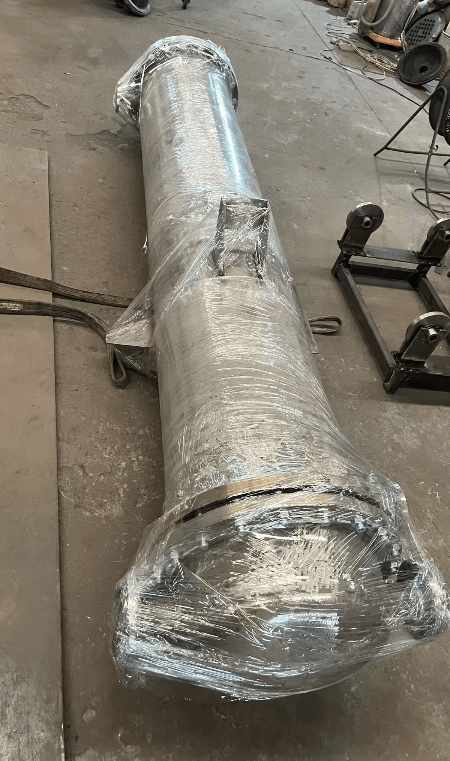

From design to final inspection, the unit underwent dimensional checks and pressure testing before protective wrapping and secure loading. With Wuxi Repicea, you receive equipment that arrives ready to run.