Expert Team of Professionals

Bringing Innovation to Heat Exchangers

Precision-Crafted Solutions: Tailored Engineering

At the heart of our approach is a dedication to customization. We partner closely with our clients, designing bespoke heat exchanger solutions that address their specific needs. Through this tailored approach, we provide exceptional efficiency, seamless integration, and a significant return on investment for every application.

Mastery in Material Science: Advanced Engineering

Our expertise lies in pushing the boundaries of material science, with a focus on cutting-edge technologies like glass-lined and silicon carbide heat exchangers. We harness this knowledge to develop products that deliver unrivaled performance in the harshest conditions, ensuring both resilience and longevity.

Trailblazers in Innovation: Numerous Patents

Innovation is in our DNA, and our extensive portfolio of patents is a testament to our relentless pursuit of excellence. Each patent we hold is a reflection of our commitment to pioneering breakthroughs in heat exchanger technology, driving enhanced performance, durability, and adaptability across industries.

Trusted by a Global Clientele: Broad Customer Base

From multinational corporations to specialized industries, our customer base spans the globe. We proudly serve leaders in sectors such as chemical processing, pharmaceuticals, energy, and food production, proving the versatility and reliability of our solutions time and time again.

Our History

11988

Founder Mr. Mao Wei initiated research on fluoroplastics and enamel technology for chemical corrosion resistance in China.

22003

Began development of Chinese enameled plate heat exchangers, establishing a robust manufacturing framework.

32012

Launched a new R&D center to innovate enameled tubular heat exchanger designs.

42017

Developed the first-generation enameled tubular heat exchanger, securing a national patent and commencing fluorine-lined workshop operations.

52019

Achieved patents for internal and external enameled tubular heat exchangers, enhancing gas material heat exchange and surpassing 10 million in domestic sales.

62020

Secured patents for a one-piece PFA tube plate and silicon carbide tubular heat exchangers, advancing heat exchange technology.

72021

Innovated high borosilicate glass and rotary enameled tubular heat exchangers, along with a high-efficiency film evaporator, obtaining patents and filling industry gaps.

82022

Established Wuxi Repicea Precision Technology to expand international trade, aiming to embrace global markets and future opportunities.

Repicea Heat Exchanger Innovations

Delivering Excellence in Every Project

Advanced Material Technology

Wuxi Repicea has pioneered the use of advanced materials in heat exchanger construction, enhancing both performance and durability. Our products utilize high borosilicate glass and silicon carbide, which offer superior resistance to corrosion and high temperatures. This innovative material application sets our heat exchangers apart in terms of reliability and longevity in harsh industrial environments.

Patented Designs for Enhanced Efficiency

Our heat exchangers are designed with patented structures that optimize heat transfer efficiency. Features such as PFA tube plates molded with steel liners and U-shape designs contribute to a larger heat transfer area, reducing energy consumption and enhancing process efficiency. These designs not only save on operational costs but also ensure compliance with high-pressure and corrosion-resistant standards.

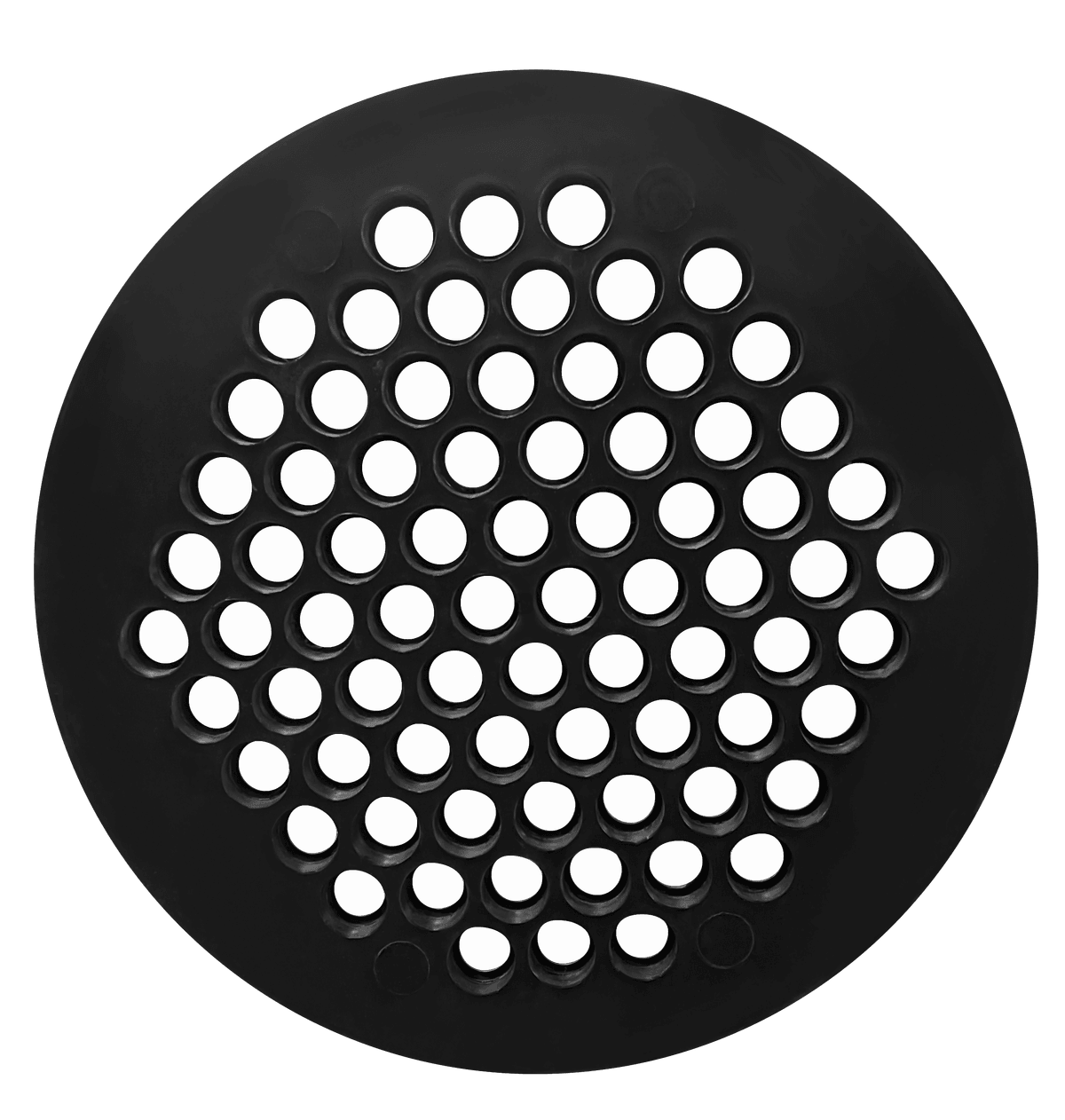

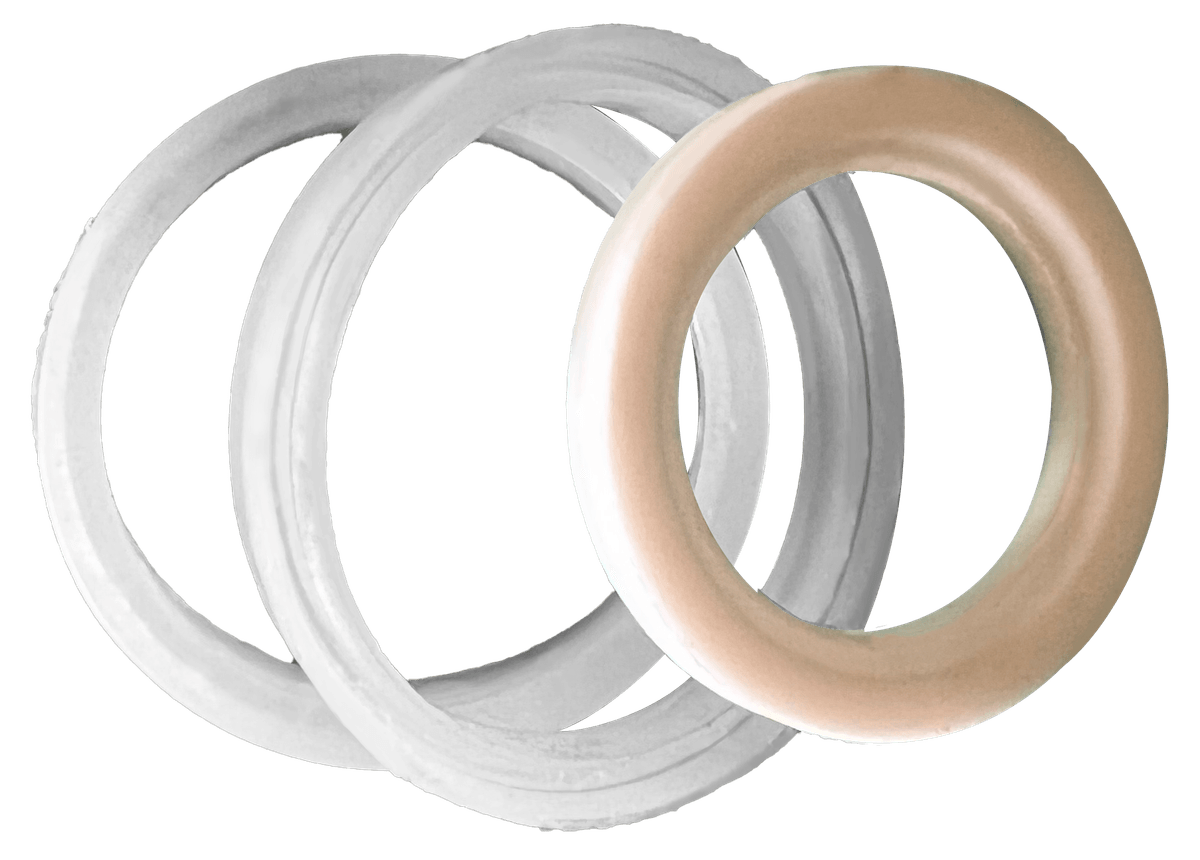

Innovative Construction for Ease of Maintenance

Wuxi Repicea's heat exchangers are constructed with ease of maintenance in mind. The external glass-lined steel construction and the use of PTFE combined gaskets facilitate easier disassembly and cleaning, reducing downtime and maintenance costs. This innovative approach minimizes the risk of leaks and extends the service life of our heat exchangers.

Broad Application Range and Customizability

Our heat exchangers are designed to meet a wide range of industrial needs, with the flexibility to handle various corrosive materials. This versatility ensures that our customers can find a heat exchanger solution that fits their unique process requirements.

Commitment to Excellence

Innovating with Integrity

Uncompromising Quality

We guarantee the highest standards in every product, ensuring durability, performance, and reliability in every solution we deliver.

Tailored Solutions

Our team designs customized solutions to meet your specific needs, maximizing efficiency and enhancing operational outcomes.

Dedicated Support

We offer exceptional customer service and technical support at every stage, ensuring your complete satisfaction and success.

4