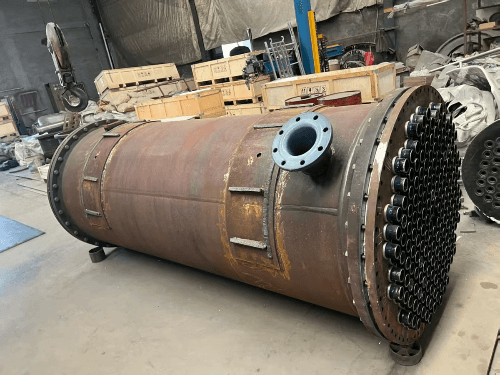

At Wuxi Repicea, two 100 m² horizontal glass-lined shell-and-tube heat exchangers have completed assembly and QA—engineered for vacuum service, corrosion resistance, and stable duty in demanding chemical processes. Each unit is purpose-built with shell-side process media and tube-side cooling water, maximizing heat transfer while protecting product purity and equipment life.

Configuration at a glance

- Heat transfer area: 100 m² per unit (2 units total)

- Orientation: Horizontal shell-and-tube

- Flow scheme: Shell-side carries process fluid, tube-side carries water

- Tube bundle: DN50 × 186 tubes, externally glass-lined (enamel) to present an inert, smooth surface to the shell-side process

- Tube sheets: φ1260 steel-lined, one-piece molded PFA (integral design for rigidity and sealing integrity)

- Shell lining: F40 fluoropolymer one-piece roller coating for a continuous, pinhole-resistant anti-corrosion layer

- Service rating: Vacuum-resistant construction for stable operation under negative pressure

Why this material stack works

- Externally glass-lined DN50 tubes

With process media on the shell-side, the tube exteriors face the chemistry. The kiln-fired enamel provides a chemically inert, ultra-smooth surface that resists acids/solvents and reduces fouling and crystallization, especially with viscous or salt-bearing streams. - F40 one-piece shell lining

The continuous fluoropolymer film delivers broad-spectrum chemical resistance and excellent release properties, protecting the shell from attack and minimizing deposits. - φ1260 molded PFA tube sheets (steel-reinforced)

The integral molded design provides dimensional stability, vacuum/pressure resilience, and leak-tight sealing, avoiding creep and deformation seen with conventional plastics under thermal cycling.

Performance benefits for operations

- High reliability under vacuum: Mechanical integrity and continuous linings maintain seal integrity in negative-pressure duties.

- Cleaner operation, less downtime: Smooth enamel and F40 surfaces discourage crystal growth and sticking, simplifying washdowns and extending run lengths.

- Efficient heat transfer: Large DN50 passages reduce pressure drop and help stabilize thermal performance with fouling-prone or viscous media.

- Compliance and purity: Inert wet surfaces protect product quality in fine chemicals, pharmaceuticals, and specialty intermediates.

Typical applications

- Acidic or solvent-rich process heating/cooling where corrosion resistance and low fouling are critical

- Vacuum evaporation/condensation loops requiring stable sealing and inert contact surfaces

- High-purity or crystallization-prone duties that benefit from smooth, non-stick linings

Built, tested, and ready

Both exchangers passed dimensional checks, lining integrity inspection, and pressure/vacuum tests. With the shell-side for process and tube-side for water clearly designated, the units are installation-ready for rapid tie-in and startup.

For custom-engineered heat exchangers—glass-lined, fluoropolymer-lined, silicon carbide, or hybrid designs—Wuxi Repicea delivers proven materials engineering and dependable lead times.