At Wuxi Repicea, precision engineering meets real-world reliability. This week, we completed loading and shipment of two vertical shell-and-tube condensers—a 30㎡ unit and a 10㎡ unit—purpose-built for corrosive, high-demand applications.

- Dual glass-lined end caps

Both ends are fitted with kiln-fired, glass-lined (enamel) sealing caps. The ultra-smooth, inert surface resists acids and solvents, minimizes fouling, and simplifies cleaning. - One-piece steel-lined, molded PFA tube sheets

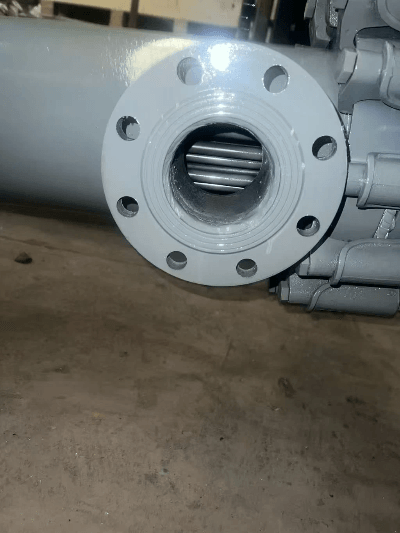

The integrated construction delivers excellent dimensional stability, leak-tight sealing, and long-term anti-corrosion performance under pressure and thermal cycling. - Φ14×2000 pressureless sintered silicon carbide tubes

SiC tubes provide high thermal conductivity, outstanding chemical resistance, and superior mechanical strength for consistent condensation efficiency.

Designed for uptime and easy integration

Both vertical condensers are engineered for compact footprints, gravity-aided condensate drainage, and straightforward tie-in to existing process lines. The glass-lined/PFA/SiC material stack-up ensures long service life, reduced maintenance frequency, and stable performance in demanding media—ideal for chemical processing, solvent recovery, and high-purity applications.

Built, tested, and shipped with care

Each unit underwent dimensional checks, sealing interface verification, and pressure testing before protective packing and dedicated loading. The result is installation-ready equipment that arrives on site in optimal condition, helping you start up faster and run longer.

If your operation requires corrosion-resistant condensers with proven heat transfer performance, Wuxi Repicea can tailor materials, geometry, and flow paths to your exact process needs.