Monday Shipment Spotlight: Vertical Glass-Lined and Silicon Carbide Shell-and-Tube Heat Exchangers

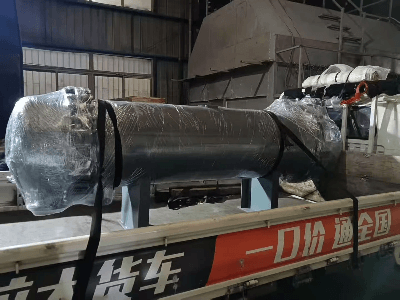

This Monday, a dedicated truck left our factory carrying three custom shell-and-tube heat exchangers for one of our chemical process customers:

- One 60 m² shell-and-tube heat exchanger

- One 20 m² new vertical glass-lined shell-and-tube heat exchanger

- One 30 m² new vertical silicon carbide (SiC) shell-and-tube heat exchanger

For the end user, this is not just another delivery. It is higher process safety, longer service life and improved energy efficiency arriving on site in a single shipment. In this article we explain why these three units were selected, and how you can decide between glass-lined and silicon carbide designs for your own projects.

Why shell-and-tube heat exchangers are still the industry workhorse

Shell-and-tube heat exchangers remain the most widely used type of heat exchanger in the chemical, pharmaceutical and fine chemical industries. They offer:

- Large heat transfer area in a compact design

- Flexible pressure and temperature ratings

- Easy integration into existing piping and support structures

- Straightforward mechanical cleaning and maintenance

When you combine this proven design with advanced corrosion-resistant materials such as glass lining and silicon carbide tubes, you get a robust solution for very aggressive media where standard metals fail quickly.

20 m² vertical glass-lined shell-and-tube heat exchanger

What is a glass-lined shell-and-tube exchanger?

A glass-lined shell-and-tube heat exchanger uses borosilicate glass tubes or a glass-lined steel surface in contact with the process fluid. This combination provides:

- Excellent resistance to a wide range of inorganic acids and many organic solvents

- A very smooth, non-stick surface that reduces fouling and simplifies cleaning

- Stable heat transfer performance over a long service life

- Low contamination risk, ideal for fine chemicals and pharmaceutical applications

Why a vertical design?

For this project, the 20 m² glass-lined exchanger was designed as a vertical unit. A vertical configuration offers several practical advantages:

- Smaller footprint in congested pipe racks and narrow process buildings

- Better drainage of condensate and cleaning liquids

- Easier connection to vertical columns, reactors or overhead condensers

- Clean, compact layouts with fewer elbows and supports

In multi-product plants where floor space is limited and cleanliness is critical, a vertical glass-lined shell-and-tube heat exchanger is often the most efficient choice.

30 m² vertical silicon carbide shell-and-tube heat exchanger

Why silicon carbide?

Silicon carbide (SiC) is a ceramic material that combines extreme corrosion resistance with very high thermal conductivity. In shell-and-tube heat exchangers, SiC tubes deliver:

- Outstanding corrosion resistance in strong acids, mixed acids and halogen-containing media

- High resistance to erosion at high flow velocity

- Very smooth tube surfaces that resist scaling and fouling

- Excellent thermal shock resistance for frequent start-up and shut-down cycles

- High thermal conductivity for compact, high-duty designs

In this Monday shipment, the 30 m² vertical SiC exchanger is used where metal alloys and even standard glass-lined equipment would suffer from rapid corrosion. The SiC tubes significantly extend service life and reduce unplanned downtime.

Benefits of a vertical SiC design

Just like the glass-lined unit, the SiC exchanger is built as a vertical shell-and-tube design. This helps:

- Save space in the plant layout

- Simplify routing of aggressive process lines

- Improve drainage and venting of highly corrosive fluids

- Make maintenance and inspection more convenient

60 m² shell-and-tube heat exchanger: capacity and system balance

Alongside the two “new generation” corrosion-resistant units, we shipped a 60 m² shell-and-tube heat exchanger. This larger unit is typically used for utilities or for high-capacity process duties, for example cooling, heating or condensing common media.

By engineering all three heat exchangers as part of the same project, we help the customer to:

- Balance the overall heat load across the system

- Match approach temperatures and pressure drops on both process and utility sides

- Reduce engineering and installation time

- Simplify spare parts, inspection and future expansion

Dedicated truck delivery: protecting high-value equipment

For glass-lined and silicon carbide shell-and-tube heat exchangers, logistics is more than just a transport booking. Both materials require careful handling to avoid damage.

This is why we arrange dedicated truck delivery for shipments like Monday’s:

- Safe handling of sensitive linings and tubes

- Custom crating and internal supports protect the shell and tube bundle from vibration and impact.

- Dedicated trucks reduce the number of loading and unloading operations.

- Short and predictable transit time

- A point-to-point route minimizes risk and ensures a reliable arrival time.

- Site teams can prepare foundations, pipe supports and cranes in advance.

- Faster commissioning

- Because equipment arrives in optimal condition with documented preservation, the plant can move quickly to installation, pressure testing and start-up.

How to choose between glass-lined and silicon carbide

For engineers and buyers, a common question is: should we choose glass-lined or silicon carbide for a new corrosive duty? The answer depends on process conditions, but the guidelines below are a good starting point.

When to choose glass-lined shell-and-tube heat exchangers

Glass-lined exchangers are usually the best option when:

- You handle multiple products within the glass compatibility range

- Operating temperatures and pressures are within standard glass-lined ratings

- Cleanability, low contamination risk and smooth internal surfaces are important

- You want a cost-effective solution with strong corrosion resistance and a long track record

When to choose silicon carbide shell-and-tube heat exchangers

Silicon carbide exchangers are recommended when:

- The medium contains high concentrations of strong acids, oxidants or halogens

- Corrosion rates on metals or standard glass-lined equipment are unacceptably high

- Very fast temperature changes or frequent thermal cycling are expected

- You need compact equipment with very high heat flux and high overall heat transfer coefficients

In many real projects, the most economical approach is a combination of both technologies: glass-lined exchangers for multi-purpose duties, and silicon carbide units for the most aggressive streams. The Monday shipment is a good example of this hybrid strategy.

What this shipment means for our customers

This dedicated truck shipment shows how we support customers from design to delivery:

- Application engineering: selecting the right material, surface area and layout

- Mechanical design: vertical and horizontal options, nozzle orientation and support design

- Manufacturing and quality control: from tube bundle assembly to final inspection

- Logistics: export packing, inland transport and dedicated trucking to the plant site

If you are planning a new project or upgrading an existing unit, our team can help you evaluate glass-lined, silicon carbide and metal shell-and-tube heat exchangers side by side and select the best option for your process.

Call to action

To discuss your next corrosive or space-limited duty, or to request a quotation for vertical glass-lined and silicon carbide shell-and-tube heat exchangers, please contact our sales team. We are ready to support your project from design and customization through to safe delivery and long-term service.