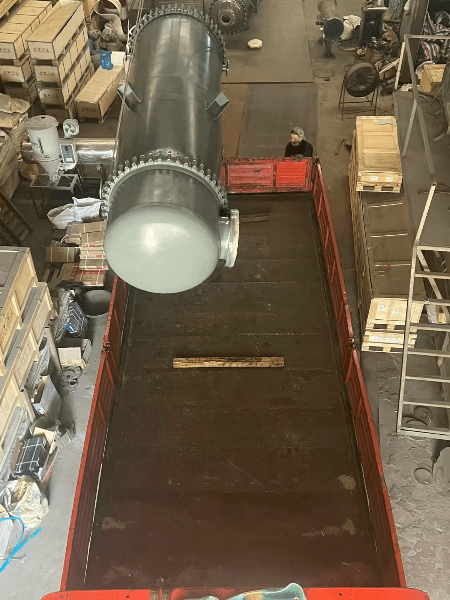

Shipment Update: 100 m² Sealed Glass-Lined Reboiler and 30 m² Horizontal Silicon Carbide Condenser Dispatched

When your process handles aggressive media—acids, chlorides, solvents, or mixed-phase streams—the heat exchanger is often the first place where reliability is tested. This week, we dispatched two corrosion-focused units by dedicated truck:

- One 100 m² new-design, fully sealed glass-lined shell-and-tube reboiler

- One 30 m² new-design, horizontal silicon carbide (SiC) shell-and-tube condenser

Both units were manufactured for chemical processing duty where corrosion resistance, tight sealing, and stable thermal performance are non-negotiable.

1) 100 m² Fully Sealed Glass-Lined Shell-and-Tube Reboiler

A reboiler sits at the heart of many distillation and evaporation systems. Operating conditions can be demanding: high temperature gradients, continuous duty cycles, and process fluids that can be both corrosive and prone to fouling.

For this shipment, the customer required a glass-lined shell-and-tube reboiler with a fully sealed structure, designed to reduce the risk of leakage and support long-term, steady operation.

Key features (project-specific):

- Heat transfer area: 100 m²

- Configuration: shell-and-tube reboiler

- Lining: glass-lined surfaces where corrosion protection is critical

- Structure: fully sealed design to improve containment and reduce maintenance exposure

In chemical and pharmaceutical operations, glass lining is often chosen where metallic alloys are either insufficient or cost-prohibitive under certain media conditions. A sealed design can further support process safety and operational continuity, especially in units that run around the clock.

Typical applications:

- Distillation column reboiling

- Solvent recovery systems

- Chemical intermediates production

- Temperature-sensitive processes requiring stable heat input

2) 30 m² Horizontal Silicon Carbide Shell-and-Tube Condenser

For the condenser, the customer specified silicon carbide (SiC) due to the operating media and the need for long service life under corrosive conditions. SiC is widely used in severe-duty environments because of its combination of corrosion resistance and thermal performance.

This unit is a horizontal shell-and-tube heat exchanger (condenser duty), designed for reliable operation and practical installation where layout height is limited or where horizontal piping integration is preferred.

Key features (project-specific):

- Heat transfer area: 30 m²

- Type: horizontal shell-and-tube condenser

- Material: silicon carbide tube-side components (per design requirement)

- Build focus: corrosion resistance and consistent condensation performance

Typical applications:

- Condensation of acidic or corrosive vapors

- Chemical processing off-gas condensation

- Heat recovery and cooling for aggressive media streams

- Processes where stainless steel or graphite is not the preferred choice

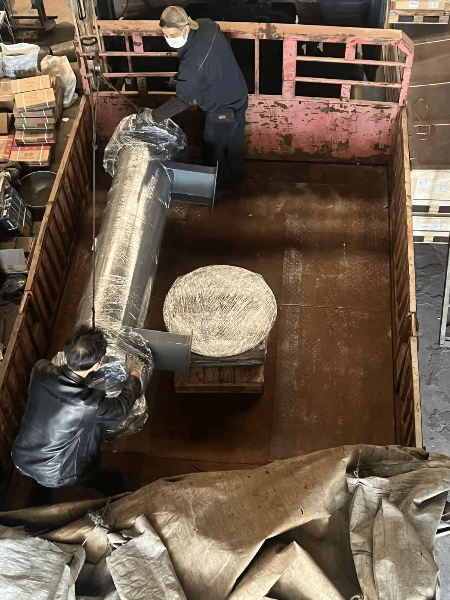

3) Packaging and Dedicated Truck Dispatch

For overseas and long-distance delivery, packaging is not an afterthought—it’s part of quality control. Both units were prepared for transport with protective measures aimed at minimizing vibration damage, impacts, and moisture exposure during transit.

This shipment used dedicated truck dispatch to control handling and reduce intermediate transfers—especially important for large equipment and for lined or ceramic-based components.

4) What This Shipment Represents for Buyers

If you’re sourcing equipment for corrosive service, the specification sheet is only part of the story. What matters in the field is repeatability: stable heat transfer, predictable maintenance cycles, and reduced risk of unplanned shutdowns.

This shipment reflects three practical priorities we see repeatedly in chemical and pharmaceutical projects:

- Corrosion resistance matched to media (glass-lined and silicon carbide options)

- Sealing and containment to reduce leakage risk and exposure

- Custom engineering around installation constraints (e.g., horizontal condenser layouts)

If you’re comparing options such as glass-lined vs. high alloy, or SiC vs. graphite, the best starting point is always the process envelope: media composition, temperature/pressure, fouling tendency, cleaning method, and expected duty cycle.