New Shipment: Heavy-Duty Glass-Lined Heater & 6 Custom SiC Condensers Head to Client

This week, Wuxi Repicea proudly dispatched a new batch of high-specification heat exchange equipment via dedicated transport, including:

1 unit of 100㎡ glass-lined shell-and-tube heater

6 units of non-standard silicon carbide condensers

The shipment showcases our commitment to advanced chemical processing solutions, featuring reinforced corrosion protection, anti-crystallization design, and custom fabrication for extreme reliability.

100㎡ Glass-Lined Heater: Built for Challenging Thermal Processes

This large-capacity glass-lined heater was designed specifically for demanding heating applications where crystallization and clogging must be avoided. Key features include:

DN50 thickened internal glass-lined heat exchange tubes

Reduces blockage and buildup, enhances flow under high-viscosity or crystallizing materials

⌀1200 one-piece steel-reinforced PFA-lined tube sheets at both ends

Delivers seamless anti-corrosion protection and long-term sealing performance

Anti-crystallization design for handling aggressive media such as salts, acids, or organics at elevated temperatures

This heater is an ideal solution for industries like fine chemicals, pharmaceuticals, and high-purity compounds that require strict process control and reliability.

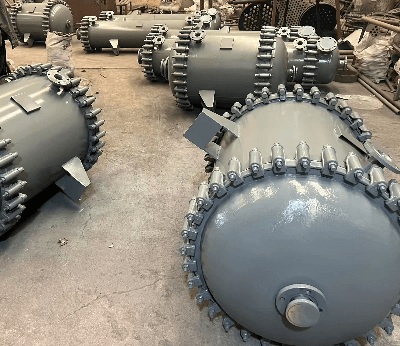

Six Custom-Built Silicon Carbide Condensers: Engineered for Precision

The shipment also includes 6 non-standard silicon carbide (SiC) condensers, each manufactured to meet unique project requirements. These units provide:

Exceptional thermal conductivity

Superior corrosion resistance in highly aggressive environments

High pressure and temperature endurance

Customization flexibility in dimensions, connections, and flow path design

All SiC units are built for long service life with minimal maintenance, making them ideal for high-performance condensation, recovery, and heat transfer systems.

Why Choose Wuxi Repicea?

At Wuxi Repicea, we don't believe in “one-size-fits-all.” Every piece of equipment is:

Individually designed for application-specific conditions

Constructed with premium materials including glass-lining, PFA fluoropolymers, and sintered silicon carbide

Backed by thorough quality inspection and pressure testing before delivery

Whether you require anti-fouling heaters, non-standard condensers, or fully customized heat exchangers, our engineering team is here to deliver optimized thermal solutions that reduce downtime and improve efficiency.

Applications Include: